WAGO在制造业的发展

您转型过程中的可靠合作伙伴

制造业面临着新的需求和挑战:成本降低和性能改善、实现工业4.0及更灵活的生产。在转型期间,WAGO将在生产的各个环节,提供专业指导,通过提供创新解决方案和可靠的产品,为您提供支持。

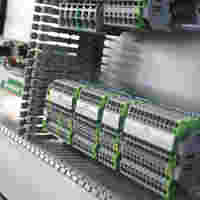

The production line of the future will not only be networked and intelligent, it will also possess some self-control and self-optimization capabilities, making it resource-efficient. For the transformation to an “intelligent factory,” the existing processes will be networked, and data on all products, machines and process data will be recorded. Automation solutions, such as the WAGO I/O System 750, are available for capturing and securely transferring data into a “Manufacturing Execution System” (MES) or product management system.

Ordering and production processes are becoming increasingly digital. The goal: Consistency and data transparency along the entire value-added chain in order to save time and lower costs. To support this horizontal integration, WAGO offers smartDATA Engineering, a solution that supports users from planning and design, to engineering, to testing and commissioning their control cabinet.

Ever greater speed, precision and flexibility – the demands made of mechanical engineering are constantly increasing. At the same time, machines and systems in production facilities are becoming more and more tailored. The right tools are essential. WAGO supplies the perfect products to help customers realize their projects, including our PROFINET fieldbus coupler and our e!DISPLAY.

Industry 4.0 and big data are opening up unexpected possibilities for new business models, so it is important to leverage valuable data collections. WAGO’s flexible and durable automation solutions reliably transfer data from the field level for use by the cloud or an MES without errors; existing systems can be retrofitted conveniently as well. Furthermore, various interfaces and fieldbuses, such as CANopen, PROFIBUS DP, DeviceNet and MODBUS-TCP, can also be utilized independently of the manufacturer.

发现更多

关于WAGO的其他话题